VAS packing hazardous material labeling plays a pivotal role in ensuring the safe transportation and handling of hazardous materials. This guide delves into the intricacies of VAS packing, providing a comprehensive understanding of labeling requirements, regulations, and best practices.

The subsequent paragraphs explore the specific labeling requirements for hazardous materials packed in VAS, including the placement, size, and visibility of labels. Additionally, the guide addresses the transportation and handling of VAS packages, emphasizing safety precautions and emergency response procedures.

1. Labeling Requirements for Hazardous Materials

Labeling hazardous materials is crucial for safety in handling, transportation, and storage. It provides vital information about the material’s hazards and precautions to ensure proper handling and emergency response.

Specific labeling requirements include the use of:

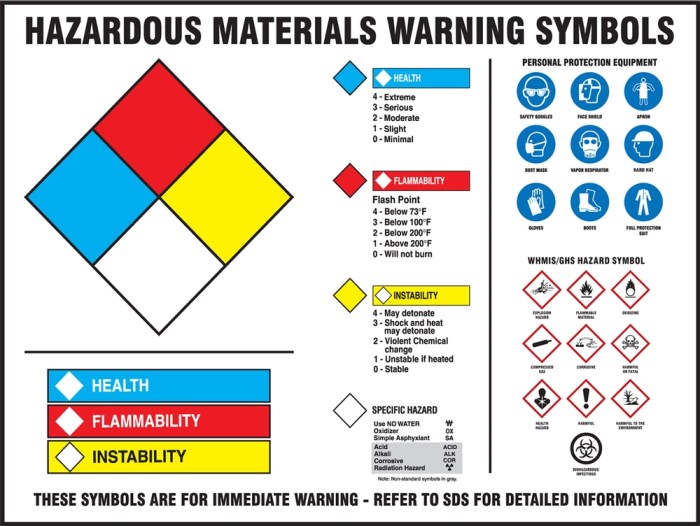

- Symbols: Pictorial representations of hazards, such as fire, explosion, or toxicity.

- Colors: Standardized colors (e.g., red, orange, yellow) to indicate different hazard levels.

- Text: Detailed information about the material’s hazards, precautionary measures, and emergency contact.

Different types of hazardous materials have specific labeling requirements based on their properties and associated risks.

2. Specifics of VAS Packing: Vas Packing Hazardous Material Labeling

VAS (Versatile Acid-Proof Suitcase) packing is a specialized packaging method designed to contain and transport corrosive materials safely.

VAS packing regulations and standards include:

- UN specifications: VAS packages must meet specific UN specifications for design, testing, and certification.

- DOT regulations: The U.S. Department of Transportation (DOT) regulates the transportation of hazardous materials, including those packed in VAS.

Hazardous materials that require VAS packing include:

- Acids

- Bases

- Corrosive liquids

3. Labeling Considerations for VAS Packing

In addition to general hazardous material labeling requirements, VAS packages have specific labeling considerations:

- Label placement: Labels must be placed on all sides of the VAS package.

- Label size: Labels must be large enough to be clearly visible.

- Label durability: Labels must be resistant to moisture, chemicals, and fading.

4. Transportation and Handling of VAS Packages

VAS packages require specific precautions during transportation and handling:

- Loading and unloading: VAS packages must be loaded and unloaded carefully to prevent damage.

- Storage: VAS packages should be stored in a secure, well-ventilated area.

- Emergency response: In case of an accident, VAS packages must be handled with appropriate personal protective equipment (PPE).

5. Regulatory Compliance and Enforcement

Compliance with labeling regulations for VAS packing is essential for safety and regulatory compliance:

- Consequences of non-compliance: Non-compliance can lead to fines, penalties, and liability.

- Regulatory agencies: The DOT and other regulatory agencies enforce hazardous materials labeling regulations.

FAQ

What are the key elements of VAS packing hazardous material labeling?

The key elements include the use of symbols, colors, and text to convey hazard information, as well as specific placement and size requirements to ensure visibility and durability.

What are the potential consequences of non-compliance with VAS packing hazardous material labeling regulations?

Non-compliance can result in fines, legal liabilities, and reputational damage, as well as pose safety risks to employees and the public.

Who is responsible for enforcing VAS packing hazardous material labeling regulations?

Regulatory agencies such as the Occupational Safety and Health Administration (OSHA) and the Department of Transportation (DOT) are responsible for enforcing these regulations.